Product Search

Quickly Find The Product You Need

Product

Contact Info

E-mail: tengsen@injenfilter.com

Business Phone: +86-18131928561

WhatsApp: +86-18131928561

Address: Ge Xianzhuang Zhen Wu Jia Na Cun Xi, Qinghe County, Xingtai City, Hebei Province

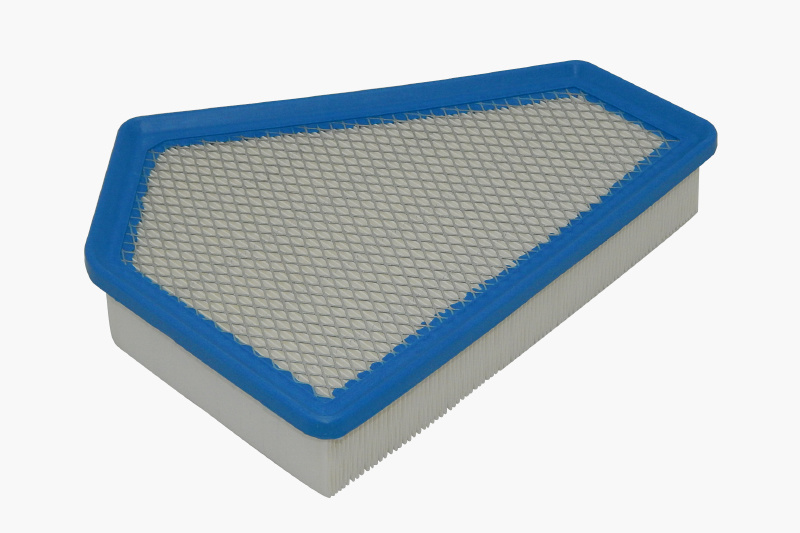

Injection molded air conditioning filter

- Commodity name: Injection molded air conditioning filter

- Product details

-

According to the filtration principle, air filters can be divided into several types: filtration type, centrifugal type, oil bath type, and composite type. The commonly used air filters in engines include inertia oil bath air filters, paper dry air filters, polyurethane filter air filters, and other types.

The inertia oil bath air filter has undergone three stages of filtration: inertia filtration, oil bath filtration, and filtration filtration. The latter two types of air filters are mainly filtered through the filter element filtration. Inertia oil bath air filters have the advantages of low intake resistance, adaptability to dusty and sandy working environments, and long service life. They were previously used on various models of car and tractor engines.

However, this type of air filter has low filtration efficiency, high weight, high cost, and inconvenient maintenance, and has gradually been phased out in automotive engines.

The filter element of the paper dry air filter is made of resin treated microporous filter paper. The filter paper is porous, loose, folded, and has a certain mechanical strength and water resistance. It has the advantages of high filtration efficiency, simple structure, light weight, low cost, and convenient maintenance, making it a widely used automotive air filter.

The polyurethane filter element of the air filter is made of soft, porous, sponge like polyurethane with strong adsorption capacity. This type of air filter has the advantages of paper dry air filters, but has low mechanical strength and is widely used in car engines. The disadvantage of the latter two types of air filters is their short service life and their unreliable operation in harsh environmental conditions.

Various air filters have their own advantages and disadvantages, but inevitably there is a contradiction between the intake volume and filtration efficiency. With the in-depth research on air filters, the requirements for air filters are also increasing. Some new types of air filters have emerged, such as fiber filter air filters, composite filter material air filters, silencing air filters, constant temperature air filters, etc., to meet the needs of engine operation.Injection molded air conditioning filter is a crucial component in the field of air conditioning systems. These filters are carefully crafted through injection molding technology, ensuring high precision and quality. The injection molded process allows for the creation of filters with complex geometries and fine details, enabling them to fit precisely within the air conditioning unit. This results in an efficient and reliable filtering mechanism that traps dust, pollen, and other airborne contaminants. These filters are designed to provide superior air purification. They have a large surface area to effectively capture and retain even the smallest particles, ensuring that the air circulated through the air conditioning system is clean and healthy. This is especially important for people with allergies or respiratory issues, as it helps to create a more comfortable and breathable indoor environment. The injection molded air conditioning filter also offers durability and long-lasting performance. Made from high-quality materials, they can withstand the rigors of continuous use and maintain their filtering efficiency over time. They are resistant to damage from temperature fluctuations, humidity, and other environmental factors . Installation of these filters is straightforward, and they can be easily replaced when needed to ensure optimal performance. Their compatibility with a wide range of air conditioning models makes them a versatile choice for various applications. In addition to their practical benefits, injection molded air conditioning filters are also aesthetically pleasing. They are designed to blend seamlessly with the overall design of the air conditioning unit, enhancing the visual appeal of the system. Overall, injection molded air conditioning filter is an essential element for maintaining a clean and healthy indoor air environment. With their advanced technology, superior performance, and user-friendly design, they play a vital role in ensuring the comfort and well-being of users. Whether in residential, commercial, or industrial settings, these filters are a reliable choice for effective air conditioning and filtration.

Key words:

Get A Quote

Related Products