Product Search

Quickly Find The Product You Need

Product

Contact Info

E-mail: tengsen@injenfilter.com

Business Phone: +86-18131928561

WhatsApp: +86-18131928561

Address: Ge Xianzhuang Zhen Wu Jia Na Cun Xi, Qinghe County, Xingtai City, Hebei Province

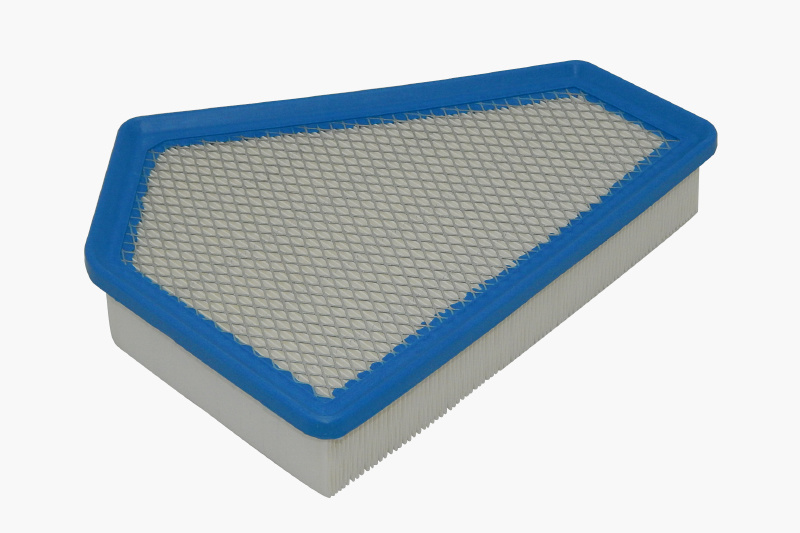

Injection molded air conditioning filter

- Commodity name: Injection molded air conditioning filter

- Product details

-

According to the filtration principle, air filters can be divided into several types: filtration type, centrifugal type, oil bath type, and composite type. The commonly used air filters in engines include inertia oil bath air filters, paper dry air filters, polyurethane filter air filters, and other types.

The inertia oil bath air filter has undergone three stages of filtration: inertia filtration, oil bath filtration, and filtration filtration. The latter two types of air filters are mainly filtered through the filter element filtration. Inertia oil bath air filters have the advantages of low intake resistance, adaptability to dusty and sandy working environments, and long service life. They were previously used on various models of car and tractor engines.

However, this type of air filter has low filtration efficiency, high weight, high cost, and inconvenient maintenance, and has gradually been phased out in automotive engines.

The filter element of the paper dry air filter is made of resin treated microporous filter paper. The filter paper is porous, loose, folded, and has a certain mechanical strength and water resistance. It has the advantages of high filtration efficiency, simple structure, light weight, low cost, and convenient maintenance, making it a widely used automotive air filter.

The polyurethane filter element of the air filter is made of soft, porous, sponge like polyurethane with strong adsorption capacity. This type of air filter has the advantages of paper dry air filters, but has low mechanical strength and is widely used in car engines. The disadvantage of the latter two types of air filters is their short service life and their unreliable operation in harsh environmental conditions.

Various air filters have their own advantages and disadvantages, but inevitably there is a contradiction between the intake volume and filtration efficiency. With the in-depth research on air filters, the requirements for air filters are also increasing. Some new types of air filters have emerged, such as fiber filter air filters, composite filter material air filters, silencing air filters, constant temperature air filters, etc., to meet the needs of engine operation.Injection molded air conditioning filters stand at the forefront of modern cooling technology, offering unparalleled levels of contaminant capture and air purification. Meticulously engineered through the injection molding process, these filters are designed to provide superior performance and longevity in maintaining clean and healthy air conditioning systems.

Crafted from high-grade, durable materials, injection molded filters boast an intricate latticework of fibers that act as a trap for airborne particles. This sophisticated matrix ensures the one-time capture of microscopic contaminants ranging from dust and pollen to bacteria and viruses, thereby preventing them from circulating back into your living or working environment.

The injection molding technique allows for precise control over the filter's structural integrity, creating a denser, more uniform filtration medium. This results in a more efficient use of the filter's surface area, leading to higher particle capture rates without sacrificing airflow. In essence, your AC system can circulate cleaner air while maintaining its operational efficiency.

Key words:

Get A Quote

Related Products